It’s been 20 years since Öhlins first experimented with semi-active suspension on Yamaha Grand Prix bikes, but the technology is finally making it to production. Öhlins introduced its Mechatronics (mechanics and electronics) system late last year for the BMW R 1200 GS, and recently released an aftermarket TTX shock for the Kawasaki ZX-10R using the technology. At the same time, BMW has gone a step beyond its Electronic Suspension Adjustment (ESA), and released information about a new Dynamic Damping Control (DDC) system. Both Mechatronics and DDC operate on the same basic premise: changing suspension action in real-time to better suit conditions, based on data collected from various sensors.

Öhlins’ Mechatronics system starts with the company’s TTX shocks, with the compression and rebound adjusters replaced with small stepper motors. The technology, dubbed TTX EC (Electronically Controlled), has been used previously on Yamaha Snowmobile models and is part of Ducati’s Electronic Suspension package on the Multistrada and 1199 Panigale models, which allows the rider to change settings through the dashboard. With Mechatronics, however, the stepper motors take their commands from a dedicated ECU which connects to the bike’s ECU. The system was first used by the Yamaha World Superbike team in 2008, and is now offered as a kit for the R 1200 GS equipped with ESA II — which has a Telelever front end and can use two TTX shocks. The Mechatronics ECU connects directly to the BMW’s CAN bus, taking sensor information already available and changing damping settings accordingly. ESA already offers Comfort, Normal and Sport modes; because the Mechatronics system interacts with the stock ECU, these riding modes are retained along with the handlebar controls. The system alters damping based on speed, automatically switching from Comfort to Normal if speed exceeds 50 mph, and from Normal to Sport at more than 75 mph. Cost for the BMW kit is $3279.

The first Mechatronics application for the sportbike market is a TTX36 shock for the ZX-10R controlled by Öhlins electronics that connect to the Kawasaki’s ECU. With software developed by Öhlins, the system changes compression and rebound settings based on engine rpm, speed and acceleration, and also based on the Power mode setting selected by the rider. There was no official word on price for the Kawasaki shock as we went to press. Given that the EC technology is already used on the Ducati Öhlins forks, and used to electronically adjust rear preload on the Multistrada model, it’s a safe bet that similarly equipped aftermarket units will soon be available.

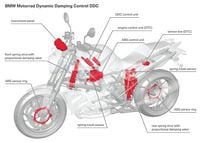

BMW's proprietary DDC likewise connects to the bike's ECU via a CAN bus, and uses that information to adjust settings. While the Mechatronics system controls damping through stepper motors acting on traditional adjusters, DDC utilizes electrically actuated, proportional damping valves inside the shocks. This arrangement has the potential to change damping settings much quicker than the Öhlins system. DDC uses information from the bike's traction control system and ABS, and can therefore be somewhat more elaborate than Mechatronics. For example, in addition to adjusting damping based on speed or acceleration, the system can change damping based on lean angle. With quick reaction, the system is capable of increasing damping as the motorcycle is leaned in to the corner, then decreasing damping as the motorcycle returns to vertical. Another example given in the press material is that front compression damping can be increased under braking, for increased stability. DDC is not available on a production model as yet, but BMW plans to introduce the system "in the near future." SR

/cloudfront-us-east-1.images.arcpublishing.com/octane/NZKPFUWBHVGYJAFQPCXWAK6BZM.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/K5ZSQFMYQZHWRFXTTW4PEWMUDM.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/D2SOSBIQQRBPTERNSOJRAW3KYY.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/DS3Q5X2VJFFAJDK2PWB3Y7K6U4.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/4KBL4JAMYRFDPEINTWATDUH7OM.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/FXADK3MVSNBRTKJ2B7TPDCCJ5Y.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/M7L2CPXO55FRFMECW7QGDPGP6E.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/T4RWGLAEHVE2VCJZOTFTNGB2KA.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/JM4QGLAHWNGHPM74OEB7FVBFSY.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/BGPNXPDDYBHD3HL6YEZQOYHXTI.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/SND5GGQV4RDPPMZBSBEGIZ4SIY.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/XUDDAPYZMZEL5EDPVDJ2DTULWI.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/M7AU2L6GAVCJVHW57LIRPDAAUQ.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/JKEJY7P43JGD5C5NJO2VJQJPUM.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/YROKYJYUQVGPHCEMPTGBWDQCKQ.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/QIHEYR66TZDAPCGMWHCWCBC4XA.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/4FTBMNZL5BD2ZHY62XXRHJW6PI.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/L2BHKRCEMFDF7O3S4REZXPDH2E.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/QHENIV3HMJCTTCXQ6O5YPTNRZ4.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/K3VNQBIAKVGIHIGBRG7QKJYLVI.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/HRU64QXT3NH2DJOFBVI53XIKCE.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/4C5HHSNJCVDZXPIJTCJBVTE2MU.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/HBKK2TCOCZFIBIVKLKZFF5NXLQ.jpg)