I read all the time in your magazine about ‘“radial-mount,” “radial-pump,” and “monoblock” brakes. What do the terms mean, and what makes those types of brakes better than other brakes?-Vince GrdinaWest Vancouver, BC, Canada

The term “radial-mount” refers to how the brake calipers are fixed to the lower fork body. Traditionally, and even currently on lower-spec bikes, calipers were mounted using bolts parallel to the axle. With radial-mount calipers, the mounting bolts are oriented radially to the axle, as the name implies. With conventional mounting, both bolts are at the front of the caliper or the trailing edge in terms of disc rotation. Radial mounting puts a bolt at the front and rear of the caliper, which increases the stiffness of the assembly and reduces how much the caliper twists when the brakes are applied. This, in turn, improves feel at the lever and helps the pads to wear more evenly.

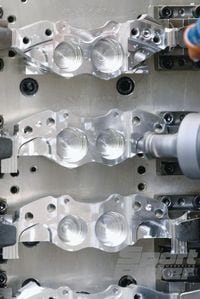

“Monoblock,” sometimes spelled as “monobloc,” refers to the brake calipers being made from one (mono) piece of metal (block). Here we are talking about conventional, multi-piston calipers that have pistons in both sides of the caliper, not sliding-pin calipers that have pistons in only one side. The easiest (and cheapest) way to manufacture such a caliper is to make it in two halves, as the piston bores and the fluid passageways can be machined from the open face. On a conventional, multi-piston caliper you can typically see the seam down the middle and the heads of the bolts holding the caliper together. Again, anything that increases strength and rigidity in the braking system improves feel at the lever, and Brembo was the first company to devise a proprietary process and tooling that allows the bores to be machined even if the caliper is cast or machined as one piece. Other manufacturers have found ways around this tricky part; Honda, for example, bores through the rear of the caliper and welds a plug in place afterward, while Yamaha does the same but uses screw-in plugs.

Radial-mount and monoblock refer to the brake calipers, but “radial-pump” refers to a type of master cylinder. On a typical master cylinder, the bore is positioned parallel to the handlebar; a radial-pump version has its bore oriented radially. A master cylinder works by converting mechanical force (you pulling on the lever) into hydraulic pressure (the plunger acting on the brake fluid). The layout of the radial-pump master cylinder allows the two leverages to be mixed and matched for best performance. In fact, Brembo offers its RCS (Ratio Click System) radial-pump master cylinder that allows the mechanical leverage to be selected between two settings. As with brake calipers, rigidity and strength also come into play here: The radial-pump master cylinder flexes less on the handlebar, improving feel.

Got a question for The Geek? Email him: srmail@bonniercorp.com

/cloudfront-us-east-1.images.arcpublishing.com/octane/NZKPFUWBHVGYJAFQPCXWAK6BZM.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/K5ZSQFMYQZHWRFXTTW4PEWMUDM.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/D2SOSBIQQRBPTERNSOJRAW3KYY.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/DS3Q5X2VJFFAJDK2PWB3Y7K6U4.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/4KBL4JAMYRFDPEINTWATDUH7OM.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/FXADK3MVSNBRTKJ2B7TPDCCJ5Y.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/M7L2CPXO55FRFMECW7QGDPGP6E.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/T4RWGLAEHVE2VCJZOTFTNGB2KA.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/JM4QGLAHWNGHPM74OEB7FVBFSY.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/BGPNXPDDYBHD3HL6YEZQOYHXTI.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/SND5GGQV4RDPPMZBSBEGIZ4SIY.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/XUDDAPYZMZEL5EDPVDJ2DTULWI.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/M7AU2L6GAVCJVHW57LIRPDAAUQ.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/JKEJY7P43JGD5C5NJO2VJQJPUM.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/YROKYJYUQVGPHCEMPTGBWDQCKQ.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/QIHEYR66TZDAPCGMWHCWCBC4XA.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/4FTBMNZL5BD2ZHY62XXRHJW6PI.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/L2BHKRCEMFDF7O3S4REZXPDH2E.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/QHENIV3HMJCTTCXQ6O5YPTNRZ4.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/K3VNQBIAKVGIHIGBRG7QKJYLVI.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/HRU64QXT3NH2DJOFBVI53XIKCE.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/4C5HHSNJCVDZXPIJTCJBVTE2MU.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/HBKK2TCOCZFIBIVKLKZFF5NXLQ.jpg)