It’s quite hard to miss Brembo’s Italian headquarters. Located in the Curno district on the outskirts of Bergamo, it not only stands on Brembo Street, there is also a kilometer-long red wall leading to the factory! Subtle it isn’t, but when you are the world’s foremost name in braking equipment you are allowed to show off a bit.

Founded in 1961 by Emilio Bombassei and his brother-in-law Italo Breda, the Brembo name is a combination of their names. A trained mechanic at the time, Emilio’s inspiration for starting his own company was born through frustration. In the 1960s there were no Italian aftermarket disc manufacturers, and when he needed a new set of discs for his car, Emilio became annoyed at the delay in them arriving from Britain and decided to make his own instead. Brembo was born. The company’s first major customers were Alfa Romeo and Pirelli in 1964. In 1970, Brembo designed its first motorcycle brake system and by 1972 Brembo’s brakes were standard fit on Moto Guzzi, Laverda and finally Ducati motorcycles. With weight becoming a crucial factor in car and bike design, Brembo made the first aluminum caliper in the late 1970s that was 50 percent lighter than the cast iron alternative and appeared on the 1980 Alfetta GTV. In 1975 Brembo started working with the Ferrari F1 team, something that led to the first carbon F1 disc in 1983, a technology borrowed from F-16 fighter jets! Brembo continued to expand and currently employs more than 6700 people worldwide and has 35 manufacturing plants and sales offices. Last year sales topped $1.25 billion and the company produced over 1 million motorcycle discs and calipers and 40 million car discs! All of the Brembo products for U.S. and European motorcycles are made in Italy and Brembo even owns its own foundries as well as machining facilities. And it doesn’t stop there; did you realize Marchesini is also owned by Brembo?

Inside Brembo's Factory

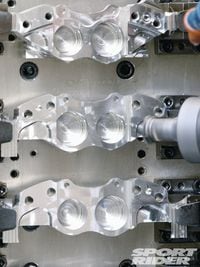

Walking into Brembo's machining factory feels like you are entering a proper old-school industrial unit. All around are racks of rough cast calipers ready to be fed into one of the 20 or so CNC machines to have their imperfections removed and their tolerances matched to within a fraction of a millimeter. Stacked next to each machine are yellow and blue boxes, each one brimming with machined components while racks of completed calipers, levers and master cylinders hang drying after being painted or anodized. Once this has been done, an army of workers (often female when it comes to the fiddly bits such as fitting pistons) complete the brake systems and place them in neat rows. It's a noisy, smelly and simply fantastic place to walk around, especially when you see a Marchesini wheel being born.

Brembo bought Marchesini in 2000 and all the wheels are machined in the same factory as Brembo’s brake systems. The black forged aluminum wheels are fed into similar CNC machines to the calipers and emerge gleaming and shiny with perfect edges and no rough areas.

The thing about the factory that is the most staggering is the sheer quantity of calipers being produced. Brembo makes around 1 million bike calipers a year, so that equates (roughly) to 4,000 a day! But this is the bike world and just as the manufacturers have to ensure their bikes are ready for the season ahead, Brembo has to step up production during winter to meet the demand of the European biking season. When we went around the factory production was at its peak and the level of activity was incredible.

Brake Check

Being something of a vital component, it's no surprise that Brembo is more than a little rigorous when it comes to testing its product. In the Italian factory, 120 people are specifically charged with ensuring that every single caliper meets the required standards. The brake components are checked using both static bench tests and dynamic tests that are designed to replicate some truly horrific use. Believe it or not, Brembo also has machines that can replicate lever "feel" using piston movement, caliper deformation and fluid displacement.

Brake systems are also durability tested using machines that replicate braking action. One machine applies the brake then twists the caliper to simulate braking. The system has to pass over 200,000 cycles without fade until the testers are satisfied. Another machine automatically pulls in the brake lever and releases it 100,000 times! And that’s just some of the static tests; the dynamic ones are even harder.

Brembo has 18 brake dynos that can run at over 140 mph and can even simulate air cooling at speed. The brakes have to be able to withstand the fade test where they are heated up to over 600 degrees and everything is checked and measured. After this the brake systems are tested on vehicles by Brembo’s test team and everything from lever feel, vibration and noise is evaluated. And speaking of noise, you know that ‘hiss’ when you touch the brake lever? That isn’t the pad skimming the disc, that’s the sound of air in the disc’s holes being compressed. This is one of the sounds that the testers deem acceptable; disc squeal isn’t. Squeal happens at high frequency (around 2000 Hz) and is due to a vibration in the brake system.

Race Department

Brembo doesn't usually let people inside its super-secret race department, but we got a sneaky peek around one of the most sensitive areas of the whole factory. Despite being in the same complex, all of the racing calipers, discs and master cylinders are machined in a separate building to the mass produced items, and there is a good reason for this. Not only are they made of completely different materials, every single caliper is unique. Believe it or not, MotoGP riders have their own calipers and no two are identical! The differences may be subtle, such as slight variations in caliper flex or piston size, but the Brembos on Casey Stoner's Repsol Honda are different to those on Dani Pedrosa's "identical" bike. And there are even different calipers for different circuits! Tracks such as Mugello and Sepang that require extreme braking have their very own specifically designed caliper — so that's a grid of different calipers that potentially changes every race! No wonder Brembo keeps huge quantities of records and individually mark every single caliper with a serial number.

Inside the race department are several CNC machines, each one costing approximately $1.25 million. Brembo’s race department is one of the very few companies who can make a true monobloc caliper from a solid lump of billet aluminum alloy thanks to these machines — and they are put to good work. The list of riders and drivers who use Brembo’s brake systems reads like a who’s who of racing, it’s virtually the whole MotoGP grid, WSB, F1, NASCAR, Indy, World Rally and more.

Like the testing area, the race department has its own brake dynos; however, these ones are very special. Not only can they run at a higher speed (188 mph), the race department’s dynos can simulate a lap of a race circuit with 100-percent accuracy thanks to computer-controlled track maps. And better than that, they can also recreate the airflow that the brakes will be subjected to as well. How clever is that?

“The Brembo calipers used in MotoGP and F1 are actually very similar,” says Roberto Pellegrini, Brembo Racing Retail & Road Performance Motorbike Market Manager. “The only major difference is that the bikes use four pistons and the cars six per caliper. Both calipers are constructed from a lithium aluminum alloy in a one-piece monobloc design with titanium pistons and both are radially mounted. I can’t tell you the sizes of the pistons, that’s a secret, but they are pretty similar. The big differences are the pressure and the clamping forces created. A MotoGP bike can reach maybe 40 bar, an F1 car can hit 100 bar of pressure, which is 5000 kilos (11,000 pounds) of clamping force! We have seen an F1 disc hit 900 degrees Celsius (1650 degrees Fahrenheit). MotoGP has no downforce so the braking is far softer and requires more lever feel, so there less chance of this kind of heat being generated. The brake fluids are slightly different; in F1 you have to use one with a very high boiling point, with MotoGP you don’t. This is due to the way F1 drivers use their brakes, they are very much on/off while a MotoGP rider needs feel. We see 90 kilograms (200 pounds) of pressure on the F1 brake pedal; MotoGP riders use one or two fingers.”

The main improvement in road brakes in the future will be weight savings, according to Roberto Lavezzi, Brembo Motorcycle Business Unit Technical Director. "We can certainly decrease the weight of calipers and brake discs. We could be ready to make carbon/ceramic brakes for road bikes but the market isn't ready for them yet. The performance isn't a problem, carbon/ceramic discs can work at low temperatures, it is a cost issue and also a safety one. A carbon/ceramic disc will last the life of a vehicle, but if there is an accident it is hard to see if the disc is damaged. The price of a carbon/ceramic brake setup would be a big issue, it would cost a lot more than a standard disc. The caliper isn't that different, the cost is in the disc itself but the weight saving is tremendous — about 50 percent lighter than a conventional disc! In the future I think we can get maybe 10 percent more performance using a conventional setup. At the moment we are looking at how to save weight by thinking of the wheel/brake/caliper as a whole picture, not separate items, something we can do as we also own Marchesini. We are testing something, it is not a perimeter brake system — we tested this and it didn't work very well, but I can't say exactly what we are testing." SR

/cloudfront-us-east-1.images.arcpublishing.com/octane/6JPU4U2H7GOYZH2ZETYQBFLR2Q.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/CXNPUJDPPBCVHIRI5H7UOCX5HY.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/RZ5QNVGN4ZDRHJIKTPHGDX3HKA.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/ZGBASNGFXVBGXAQGDM6EWLNFXA.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/54BEFUE3XBDCTCAYUYQNZGAJV4.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/5XF2ZKSOR5G7TO23KSYT4JADTU.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/VHUK3FH6WFHLTHN7CKCATU36LM.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/HC4P3CYOXFF3NGXCQTGORFRYNY.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/ZNANUJGGKVBIFH3VRZ32BYC454.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/JACAJ4MPKJBTDBOZRTHXZAKLTA.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/7L3YWQXRBRECXMWQ6NBVAHU2EY.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/BPD5CKH5IFGDLG67Y24UMOXXGA.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/CHQ32B6TVBEPVFNPERY3AB2H3M.jpg)